A waveguide is a structure that guides electromagnetic waves, such as light, through a path without allowing them to escape. It is commonly used in various applications, including telecommunications, radar systems, and microwave ovens. There are 8 main different types of waveguides available, each with its own unique characteristics and uses. Understanding the different types of waveguides can help in selecting the most suitable one for a specific application.

Rectangular Waveguide

As the name suggests, this type of waveguide has a rectangular cross-section. The walls of the waveguide are made of conductive material, such as metal, to prevent the leakage of electromagnetic waves. Rectangular waveguides are commonly used in microwave and millimeter-wave applications, such as wireless communication and radar systems. They are relatively easy to fabricate and have low loss, making them suitable for high-power applications.

Rectangular waveguides have a number of advantages over other types of waveguides. First, they have a larger cross-sectional area, which allows for the transmission of higher power levels. Second, they have a lower cutoff frequency, which means they can transmit lower frequency signals. Finally, they have a higher power handling capacity, which makes them suitable for high-power applications.

One disadvantage of rectangular waveguides is that they have a limited bandwidth. This means they can only transmit a narrow range of frequencies. Additionally, rectangular waveguides are more difficult to fabricate than other types of waveguides, such as circular waveguides.

In summary, rectangular waveguides are commonly used in microwave and millimeter-wave applications due to their ease of fabrication, low loss, and high power handling capacity. They are particularly well-suited for high-power applications, such as satellite communication and radar systems. However, they have a limited bandwidth and are more difficult to fabricate compared to other types of waveguides.

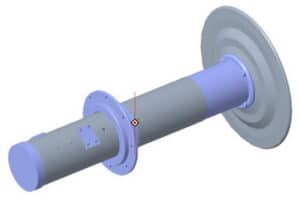

Circular Waveguide

Circular waveguides are waveguides with a circular cross-section. They are used to guide electromagnetic waves, typically at microwave frequencies. Circular waveguides are commonly used in wireless communications radar systems, and microwave backhaul. They have the advantage of being able to handle higher power levels than rectangular waveguides and are less prone to interference from external sources.

Circular waveguides are typically made of a conducting material, such as copper or aluminum. The inner surface of the waveguide is often coated with a thin layer of material to reduce losses due to electrical resistance. The circular cross-section allows for the propagation of electromagnetic waves in a cylindrical shape.

The operation of circular waveguides is based on the principle of total internal reflection. When an electromagnetic wave enters the waveguide, it reflects off the inner walls and continues to propagate along the length of the waveguide. The waveguide acts as a waveguide for the electromagnetic waves, confining them within the hollow center.

The size of the circular waveguide is determined by the operating frequency. The wavelength of the electromagnetic wave must be smaller than the diameter of the waveguide for efficient propagation. The most common sizes of circular waveguides are standardized and given designations such as WR-90 or WR-137, where the number represents the approximate diameter of the waveguide in mils.

Circular waveguides have several advantages over rectangular waveguides. They can handle higher power levels, making them suitable for high-frequency applications. They are also less prone to interference from external sources, as the circular shape helps to minimize the coupling of external electromagnetic fields. Additionally, circular waveguides have a lower cutoff frequency, allowing them to transmit lower frequency signals compared to rectangular waveguides.

In conclusion, circular waveguides are widely used in high-frequency applications due to their ability to handle high power levels and their resistance to interference. They are commonly used in satellite communication, radar systems, and microwave ovens.

Coaxial Waveguide

A coaxial waveguide is a type of transmission line used to transmit high-frequency electromagnetic waves. It consists of two concentric conductors, an inner conductor and an outer conductor, separated by a dielectric material. The inner conductor carries the signal, while the outer conductor serves as a shield to prevent interference from external electromagnetic fields.

The inner conductor of a coaxial waveguide is typically a solid wire or a hollow tube, while the outer conductor is usually a cylindrical metal tube. The dielectric material between the two conductors is often air, but it can also be a solid or liquid dielectric.

Coaxial waveguides have several advantages over other types of transmission lines. They have a low loss, meaning that the signal does not degrade significantly as it travels through the waveguide. They also have a high power handling capability, allowing them to transmit high-power signals without distortion. Additionally, coaxial waveguides have a high level of isolation between the inner and outer conductors, which helps to prevent interference.

Coaxial waveguides are commonly used in applications such as telecommunications, radio frequency (RF) and microwave systems, and high-speed data transmission. They are also used in medical imaging devices, such as magnetic resonance imaging (MRI) machines, and in scientific research equipment.

In conclusion, coaxial waveguides are a type of transmission line that use two concentric conductors separated by a dielectric material to transmit high-frequency electromagnetic waves. They are widely used in various applications due to their low loss, high power handling capability, and high level of isolation.

Optical Waveguides

Optical waveguides are structures used to confine and guide light along a specific path or within a certain area. They are used in a wide range of applications, including telecommunications, data transmission, and sensing.

There are several types of optical waveguides, including fiber optic waveguides, planar waveguides, and photonic crystal waveguides. Each type has its own unique properties and advantages.

Fiber optic waveguides are the most common type of optical waveguide. They consist of a cylindrical core made of a high-refractive-index material, surrounded by a cladding material with a lower refractive index. The core and cladding materials are carefully chosen to create total internal reflection, which allows light to propagate along the length of the fiber with minimal loss. Fiber optic cables, which are made up of multiple fiber optic waveguides, are used to transmit light signals over long distances with high bandwidth and low loss.

Planar waveguides are another type of optical waveguide that are fabricated on a flat substrate, such as glass or silicon. They consist of a thin layer of high-refractive-index material sandwiched between two layers of lower-refractive-index material. Light is guided through the high-index layer by total internal reflection. Planar waveguides are commonly used in integrated optical circuits, where multiple optical components, such as lasers, modulators, and detectors, are integrated on a single chip.

Photonic crystal waveguides are a more advanced type of optical waveguide that are based on the concept of photonic crystals, which are periodic structures that exhibit photonic band gaps. These waveguides use the periodicity of the crystal structure to confine and guide light within a certain region. Photonic crystal waveguides can be designed to have very small dimensions, allowing for highly compact and efficient optical devices.

In summary, optical waveguides are essential components in the field of optics and photonics. They enable the transmission and manipulation of light in a controlled manner, allowing for the development of high-performance optical devices and systems.

Dielectric Waveguides

Dielectric waveguides work based on the principle of total internal reflection, similar to metallic waveguides. However, instead of using a conducting material to confine and guide the electromagnetic waves, dielectric waveguides use materials with high dielectric constants.

The high dielectric constant of the material allows for a larger electric field to be generated within the waveguide, which in turn allows for a greater amount of energy to be carried by the wave. This results in a higher power handling capability compared to metallic waveguides.

Dielectric waveguides are typically made from ceramics or polymers. Ceramics, such as alumina or quartz, offer excellent electrical properties and can handle high power levels. Polymers, on the other hand, are more flexible and can be easily shaped into different geometries, making them suitable for a wider range of applications.

One of the main advantages of dielectric waveguides is their low loss characteristics. The dielectric material used in these waveguides has very low electrical conductivity, which minimizes the power loss due to resistive heating. This makes dielectric waveguides highly efficient for transmitting and guiding electromagnetic waves.

Dielectric waveguides are commonly used in microwave and millimeter-wave applications, such as radar systems, satellite communications, and wireless networks. They can be designed to operate at specific frequencies and can be easily integrated into complex systems.

In conclusion, dielectric waveguides are an important class of waveguides that offer low losses and high power handling capabilities. They are made from materials with high dielectric constants, such as ceramics or polymers, and are commonly used in microwave and millimeter-wave applications.

Slab Waveguides

Slab waveguides are often made using semiconductor materials such as silicon or indium phosphide. The high refractive index layer, also known as the core, guides the light along its path, while the lower refractive index layers, called cladding, confine the light within the core.

The structure of a slab waveguide can be thought of as a three-layer system, with the core in the middle and the cladding layers on either side. The thickness of the core layer is typically a few micrometers, while the cladding layers are usually several times thicker.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.