Hey there! If you’ve ever looked into setting up a long-range communication link, you’ve probably waded into the world of parabolic dish antennas. I get it, the specs can be overwhelming. But one of the most fundamental choices you’ll make is the reflector itself: a classic solid dish or a modern, 4-part “pizza” style?

A solid reflector is a single, continuous dish offering maximum durability and the most efficient signal reflection, making it ideal for harsh conditions or when peak performance is critical. A 4-part pizza reflector is lighter, easier to transport, and often cheaper, but the seams can be a minor weak point for durability and signal perfection.

But that’s just the quick answer. The real devil is in the details, and choosing the right one for your project depends on a classic battle: ultimate performance versus cost and convenience. Let’s break it down so you can make the perfect choice.

The Nitty-Gritty of Reflector Design

Before we pit them against each other, let’s get on the same page about what these reflectors are. Think of a parabolic reflector as the antenna‘s giant ear, designed with a special curve to catch radio waves and bounce them perfectly to a single focal point. How that “ear” is constructed makes all the difference.

The Solid Reflector: The Old Faithful

When you picture a classic satellite dish, you’re probably thinking of a solid integrated reflector. It’s exactly what it sounds like: a single, continuous dish surface.

This style is typically formed from materials like aluminum alloy or steel using methods like hydraulic pressure forming or spinning to get that perfect parabolic shape. The key takeaway is its seamlessness. It provides a smooth, uninterrupted surface that’s fantastic at focusing signals precisely where they need to go.

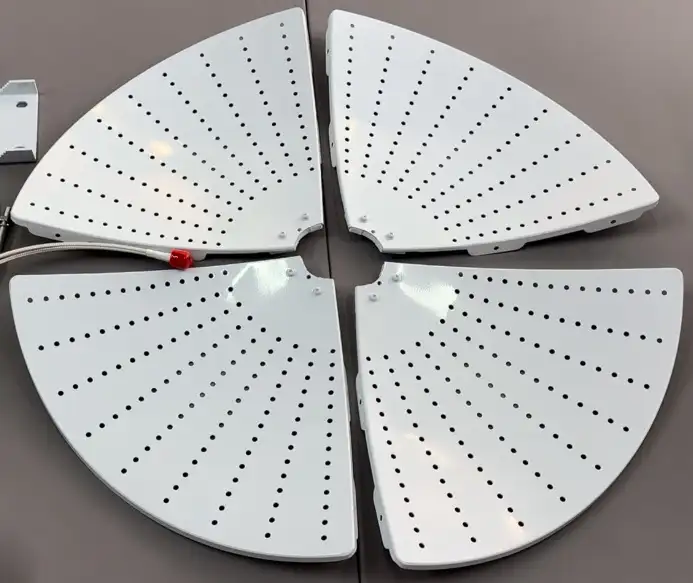

The 4-Part “Pizza” Reflector: The Convenient Contender

The “pizza type” reflector is a modern twist on traditional dish design. Instead of a single, solid piece, the dish is made up of four separate “slices” that bolt together to form the full parabola. These segments are typically produced using stamping or die-casting methods, which makes manufacturing more efficient and cost-effective.

So, why go this route? It’s all about convenience. Shipping and handling are much easier when you’re dealing with smaller pieces rather than one huge, bulky dish. The reflector comes in a compact box, making it simple to carry up a ladder or transport to a remote site. And just like the solid dish reflector, the four parts are fully assembled on the ground before being mounted to the mast or pole on the tower. Pretty handy, right?

The Head-to-Head Battle: Solid vs. 4-Part Pizza

Alright, now for the main event. Let’s compare these two styles across the factors that matter most to you: performance, durability, logistics, and cost.

Performance and Signal Efficiency

When it comes to pure, unadulterated performance, the solid dish generally takes the crown.

Solid Reflector: Its perfectly smooth, continuous surface offers the highest possible efficiency in signal reflection. To get the best gain, the shape of the dish needs to be accurate to within a tiny fraction of a wavelength, and a single, rigid piece is the best way to guarantee that precision across the entire surface.

4-Part Reflector: While very, very good, it’s not “perfect“. The seams where the four parts join, no matter how precisely engineered, can introduce minuscule surface errors. These tiny imperfections can cause a small amount of signal scattering, which might slightly reduce the overall gain and efficiency compared to a perfectly made solid dish. For 99% of applications, this difference might be negligible, but for those pushing the absolute limits of communication, it’s a factor.

Winner: Solid Reflector

Durability and Weather Resistance

You’re likely mounting your antenna outdoors, where it will face wind, rain, and temperature swings for years. Durability is not just a “nice-to-have.”

Solid Reflector: This design is inherently more durable and better equipped to handle harsh environmental conditions. With no seams, there are no potential weak points for water to seep in, for ice to form and expand, or for corrosion to start. It’s a fortress.

4-Part Reflector: The joints are the Achilles’ heel. While well-designed pizza reflectors are built to be robust, the seams are still the most likely points of failure over a long period. They are more susceptible to issues from thermal expansion and contraction, which could, over many years, slightly affect the dish’s perfect parabolic shape.

Winner: Solid Reflector

Logistics: Shipping and Installation

This is where the tables turn dramatically. Getting the antenna from the factory to its final destination can be a huge part of the challenge.

Solid Reflector:Let’s be honest, they can be a pain. A solid dish is heavy, bulky, and awkward to handle. Transporting a large one can require a flatbed truck and specialized equipment, adding significant cost and complexity to the project.

4-Part Reflector: This is the pizza reflector’s time to shine. It can be disassembled and packed into a much smaller, more manageable box. This makes it cheaper to ship and infinitely easier to transport to the installation site, whether that’s a crowded rooftop or a remote tower. The lower weight also makes it easier to handle during the installation itself.

Winner: 4-Part Pizza Reflector

Cost and Manufacturing

For a lot of projects, cost really is the bottom line. The manufacturing method and material selection can make a big difference in the final cost.

Solid Reflector: Making a solid reflector typically involves spinning or hydraulic pressing, and you also have to consider the high expense of shipping such a large, rigid item. All in all, solid dishes usually end up being more expensive.

4-Part Reflector: The 4-part pizza reflector, though, is usually produced using either stamping or die-casting. Both methods are quite efficient, especially for large production runs. And since the reflector comes in smaller pieces, it’s much cheaper and simpler to transport. When you put it all together, the 4-part pizza reflector tends to be the more cost-effective option.

Winner: 4-Part Pizza Reflector

So, Which One is Right for You?

As you can see, there’s no single “best” choice—it’s about the best choice for your specific needs. It all boils down to a classic engineering trade-off.

You might prefer a Solid Reflector if…

Maximum performance is non-negotiable. For applications like radio astronomy, critical data backhaul, or communicating over extreme distances, every fraction of a decibel in gain matters.

The antenna will be in an extremely harsh environment. If you’re dealing with high winds, heavy ice loads, or marine conditions, the superior structural integrity of a solid dish provides peace of mind.

Shipping and installation logistics are not a major hurdle. If you have the means to transport and mount a large, heavy dish, then its benefits are worth it.

A 4-Part Pizza Reflector could be your best bet if…

You are budget-conscious. For many commercial and consumer applications, the cost savings in both the product and its shipping can be a massive advantage.

Ease of transport and installation is a priority. If you need to ship antennas globally, or if your installation team has to carry gear up several flights of stairs, the convenience of a sectional dish is a game-changer.

You can accept a tiny, often theoretical, trade-off in performance. for significant gains in practicality and cost. For most WiFi, 5G, or CCTV applications, the performance is more than sufficient.

Conclusion

Ultimately, the choice between a solid and a 4-part pizza reflector is a story of performance versus practicality. The solid dish is the uncompromising workhorse, while the 4-part dish is the clever, convenient, and cost-effective solution.

So, which is more critical for your next project: squeezing out that last drop of performance, or streamlining your logistics and budget?